What is Engineered Hardwood Flooring? A Comprehensive Guide

Manufacturers glue together multiple layers of wood or plywood to create engineered hardwood flooring. The topmost layer, known as the wear layer or veneer, is made of real hardwood, giving the flooring its classic aesthetic appearance and feel that resembles solid hardwood flooring. Beneath the veneer lie several layers of plywood or high-density fiberboard (HDF) in a cross-grain pattern arrangement. This construction method adds stability to the flooring and helps minimize the expansion and contraction that can occur due to changes in humidity.

Engineered hardwood flooring has recently emerged as a versatile and visually attractive option. Unlike traditional solid hardwood flooring, engineered hardwood comprises multiple layers that blend the charm of real hardwood with improved durability and stability. In this article, we will delve more into the details of engineered hardwood flooring.

History of Engineered Hardwood Flooring

Engineered hardwood flooring emerged in the 1960s and 1970s as a response to the limitations of solid hardwood. It addresses issues such as moisture susceptibility and temperature changes. It consists of multiple layers, including a top veneer of real hardwood and core layers of plywood or HDF. This innovative construction provides enhanced stability and resistance, making it suitable for various environments. The popularity of engineered hardwood flooring has grown due to its advantages over solid hardwood, offering stability, easy installation, and cost-effectiveness without compromising visual appeal. Ongoing technological advancements continue to refine its characteristics, solidifying its place as a durable and versatile flooring option in the modern era.

Types of Engineered Wood Flooring

Engineered wood flooring is flooring made by combining real wood with other materials. Unlike solid hardwood flooring, which is made from a single piece of wood, engineered wood comprises multiple layers. The layers strategically bond together to enhance the structural integrity and performance of the flooring. Here’s a broader context on the types of engineered wood flooring:

Laminated Veneer Lumber

Laminated Veneer Lumber (LVL) is a durable wood product made by gluing thin layers of wood together, usually from pine or fir. It is renowned for its strength, stability, and reliability. This type of lumber is widely used in construction for beams, headers, and other structural components because it can span long distances without warping or shrinking, outperforming regular solid wood.

Laminated Strand Lumber

Laminated Strand Lumber (LSL) is a strong flooring made by pressing wood strands with glue. During manufacturing, the operators align the strands parallel to each other, which gives the material consistent strength. LSL is often used for framings, such as studs and beams, because it offers an eco-friendly and budget-friendly option compared to regular lumber. Builders and architects prefer LSL because of its consistent quality and contribution to sustainable construction practices.

Plywood

Plywood is a strong and versatile wood made by gluing thin layers with grains running in different directions. This unique structure makes it resistant to warping and adds strength. Builders commonly use it to construct floors, roofs, and furniture. Plywood is available in different types, depending on its use area (indoors or outdoors). It is a popular choice due to its reliability and adaptability for various other purposes.

Composite Board

Composite board is a durable wood-based product made by mixing materials such as wood fibers with adhesive. Builders use it to make floors, roofs, and furniture. Particleboard and MDF are examples of different types of composite boards, each suitable for specific projects. Composite boards are reliable and don’t easily warp, making them popular in the construction and woodworking industries. Additionally, some composite boards utilize recycled materials, making them an eco-friendly choice.

Engineered Wood Flooring Materials

There are various wood species available for you to choose from. Each wood has a different grain, pattern, color, and tone. Learn more about them in this section:

Oak

Oak wood flooring is known for its durability and timeless appearance. It adds a classic and warm feel to spaces, making it a popular choice for both traditional and modern interiors.

Hickory

Hickory-engineered wood flooring is renowned for its hardness and distinctive grain patterns. Its rustic charm and robustness make it suitable for high-traffic areas.

Maple

Maple-engineered wood flooring has a smooth and consistent grain, making it perfect for contemporary and minimalist designs. It offers a clean and elegant appearance with a light and bright look.

Birch

Birch-engineered wood flooring has a fine grain and consistent coloring. It adds a touch of sophistication to interiors and is known for its durability, making it suitable for various spaces.

Bamboo

Bamboo-engineered wood flooring is an eco-friendly option known for its sustainability and unique grain patterns. It provides a distinct, natural look while contributing to environmentally conscious design choices.

Layers of Engineered Wood Flooring

Crafters have designed the layers of engineered wood flooring to enhance its durability and stability. These layers work in harmony to create a flooring option that combines the natural beauty of wood with improved structural integrity. The engineered construction helps prevent warping or shrinking, making it a practical choice for various environments and applications. Here’s a brief overview of the key layers:

Veneer Layer

The top layer of engineered wood flooring is the veneer layer. It is made of real wood and provides a surface appearance. Common wood species for the veneer are oak, hickory, and maple. The varying thickness of the veneer layer influences the ability to refinish the flooring.

Core Layer

The layer beneath the surface of the flooring is called the core layer, which crafters usually make from plywood, high-density fiberboard (HDF), or another composite material. The purpose of the core layer is to enhance the floor’s strength and stability. The grains of each layer in the core are typically positioned at right angles to increase dimensional stability and reduce the risk of expansion or contraction.

Backing Layer

The backing layer is the bottommost layer of engineered wood flooring. It provides additional support and stability. The backing layer is often made of the same material as the core layer, contributing to the overall strength of the flooring.

Advantages of Engineered Wood Flooring

Engineered wood flooring has become popular among homeowners and designers because of the numerous advantages that set it apart from traditional solid wood options. This flooring option has gained recognition for its unique features, such as resistance to warping, easy installation processes, and eco-friendliness. In this section, we will explore the benefits of using engineered wood flooring.

Price

Engineered wood flooring is often more cost-effective than solid wood flooring, making it a budget-friendly option for homeowners.

Wrap Resistance

Engineered wood flooring is more resistant to warping due to its layered construction, providing enhanced stability in varying humidity levels.

Easy Installation

Engineered wood flooring is popular for DIY projects or those seeking quicker installation because the design aims for straightforward installation using click-and-lock or tongue-and-groove systems.

More Resistant to Temperature Change

The layered structure of engineered wood flooring helps it adapt better to temperature changes, reducing the risk of expansion associated with fluctuations in environmental conditions.

Eco Friendly

Many engineered wood flooring products use sustainable and recycled materials in their construction, contributing to eco-friendly practices in the flooring industry.

Add Value to Your Home

Engineered wood flooring is considered an attractive feature in homes and can add value to the property. Its aesthetic appeal and durability make it an investment that can enhance a home’s overall value.

Disadvantages of Engineered Wood Flooring

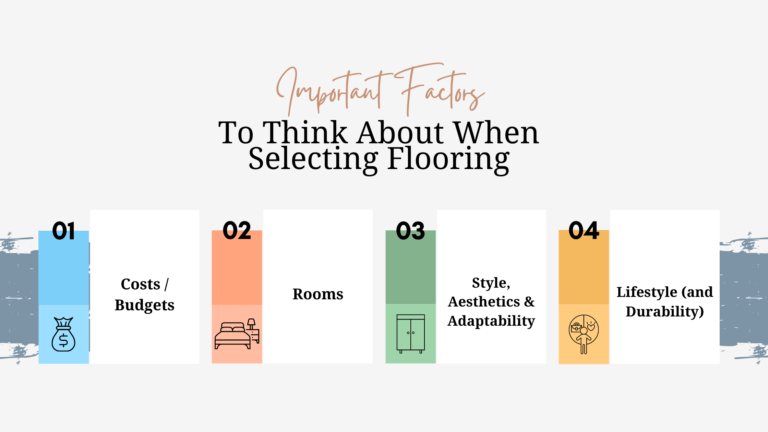

While engineered wood flooring offers multiple advantages, it has some shortcomings, which are sometimes benefits in disguise. It’s helpful to be aware of certain considerations that come with this flooring option for making informed decisions. Understanding the disadvantages can help homeowners decide when selecting flooring materials for their spaces. Here are some demerits of engineered wood flooring:

Maintenance Needs

Engineered wood flooring is known for its durability, but like all good things, it thrives with proper care. Regular cleaning and mindful practices to prevent moisture buildup can greatly extend the life and beauty of your engineered wood floors.

Quality Variations

The strength and resilience of engineered wood flooring can vary depending on the quality and construction. You can enjoy a floor that withstands heavy traffic and day-to-day wear by choosing a high-quality option, ensuring long-term satisfaction and durability.

Color Longevity

While engineered wood flooring can be sensitive to prolonged sunlight exposure, leading to some fading, we can easily manage it. Simple solutions like area rugs and window coverings can protect your floors, helping to preserve their color and charm for years to come.

Where to Use Engineered Wood Flooring?

Engineered wood flooring has become increasingly popular due to its versatile nature and durability, making it suitable for different areas within a house. You must consider factors such as moisture resistance and stability to determine where to use engineered wood flooring. In this section, we’ll delve into the optimal spaces for this type of flooring.

Kitchen

Engineered wood flooring suits kitchens due to its stability in varying humidity levels. However, it would help if you promptly wiped any spills to prevent potential water damage.

Basements

You can install engineered wood flooring in basements, but ensure sufficient moisture control. Its layered construction helps resist the effects of humidity, making it a viable option below ground level.

Other High-Traffic Areas

Engineered wood flooring is an excellent choice for high-traffic areas such as hallways, living rooms, or entryways. Its durability and resistance to warping make it well-suited for spaces with frequent foot traffic.

Installment Process of Engineered Wood Flooring

Proper installation of engineered hardwood requires following several steps. To ensure correct installation, follow the instructions below for effective results.

- Subfloor Preparation: Ensure a clean, dry, and level subfloor.

- Acclimation: Allow the planks to adjust to the room’s conditions.

- Moisture Barrier: Install a moisture barrier based on the subfloor type.

- Layout Planning: Plan the layout, considering room features.

- Starting Point: Determine the starting point, often along the longest wall.

- Installation Method: Follow the chosen method—floating, glue-down, or nail-down.

- Plank Installation: Install the planks following the layout, using spacers for expansion.

- Cutting Planks: Cut the planks as needed for precision.

- Securing Planks: Secure the planks through nailing, gluing, or clicking.

- Finishing Touches: Install baseboards or molding for a polished look.

What Should be the Optimal Thickness of the Engineered Hardwood Flooring?

The optimal thickness of engineered hardwood flooring depends on usage and personal preference. Generally, the thickness ranges from 3/8 to 3/4 inches, while a thickness of 1/2 to 5/8 inches is commonly used in residential areas, striking a balance between stability and cost. For commercial settings or high-traffic areas, A thicker option like 3/4 inch, can enhance durability in commercial settings or high-traffic areas. When consulting with your supplier, consider factors such as subfloor condition, installation method, and foot traffic to determine the most appropriate thickness for your needs.

Why Choose Engineered Hardwood Flooring?

Engineered hardwood flooring is a superior choice due to its versatility, stability, and cost-effectiveness. It offers various wood species, finishes, and styles. The layered construction of engineered hardwood minimizes the impact of moisture and temperature changes, making it suitable for various environments. Additionally, engineered hardwood’s cost-effective nature, installation flexibility, and environmental friendliness contribute to its popularity. Engineered hardwood provides an authentic look without common issues like warping. It offers wide plank options, making it a functional and aesthetically pleasing flooring solution for different spaces.

How do you Maintain Engineered Hardwood Flooring?

Following proper maintenance practices is important to preserve the aesthetic appeal and durability of engineered hardwood flooring. Engineered hardwood flooring is an investment in the charm of natural wood, with a genuine wood surface and improved stability. To ensure it lasts, it’s crucial to understand how to care for and maintain engineered hardwood flooring. Explore the various ways to maintain engineered wood flooring.

- Regular Cleaning: Sweep or vacuum regularly using a soft-bristle broom or a vacuum with a hardwood floor attachment to prevent scratches from dirt and debris.

- Damp Mopping: Wipe the floor with a damp mop using a pH-balanced hardwood floor cleaner. Avoid excessive water, as it can damage the wood.

- Immediate Spill Cleanup: It’s important to clean up spills quickly to prevent potential damage. Use a dry or slightly damp cloth to wipe the affected area.

- Avoid Harsh Cleaners: Avoid using harsh chemicals, abrasive cleaning methods, or steam cleaners, as they can damage the wood and its finish.

- Protective Furniture Pads: When moving or rearranging furniture, attach soft pads to the legs to prevent scratches.

- Area Rugs and Mats: It’s a good idea to place rugs or mats in high-traffic areas and entryways to collect dirt and prevent wear. Make sure to choose rugs with a breathable backing to prevent moisture from being trapped.

- Control Humidity: To prevent the expansion or contraction of engineered wood, maintain consistent indoor humidity levels. Use a humidifier in dry conditions and a dehumidifier in humid conditions.

- Avoid High Heels and Pets’ Claws: Minimize the risk of scratches by avoiding high heels and keeping pets’ claws trimmed.

- Routine Inspections: It is important to regularly check your flooring for any signs of damage, scratches, or wear. If you find any issues, address them promptly to prevent further damage.

- Professional Maintenance: Based on the manufacturer’s recommendations and the flooring’s condition, consider getting professional cleaning and maintenance services, especially deep cleaning and refinishing.

Hardwood Flooring vs Engineered Wood Flooring

| Aspect | Engineered Wood Flooring | Hardwood Flooring |

| Cost | Generally more affordable | Typically higher cost |

| Lifespan | Varies, often 20-30 years | Can last for 30 to 100 years |

| Material | Plywood or HDF core with a hardwood veneer | Solid wood planks |

| Moisture | Better resistance to moisture, suitable for basements | Prone to warping with moisture exposure |

| Core | Plywood | Hardwood |

| Cleaning | Suitable for damp mopping | Do not use a wet mop |

| Sizes | Wide range of plank sizes and thicknesses | Standard sizes with limited thickness options |

Upgrade Your Flooring with the Timeless Elegance of Engineered Hardwood

Engineered hardwood flooring is a great choice for those who want a durable and practical option that still offers a visually appealing look. Its construction, featuring layers of real wood, ensures stability and addresses issues like moisture and temperature changes. With various wood species and finishes, engineered hardwood provides a versatile solution for different settings. With its growing popularity, retailers can benefit by highlighting its advantages, such as cost-effectiveness, resistance to wrapping, and easy installation.

At Villagio Wood Flooring, we understand the changing preferences in the flooring industry. As retailers strive to meet the demand for attractive and long-lasting flooring, we invite you to explore our offerings. Our engineered hardwood options combine innovation with timeless appeal, offering your clientele a lasting and beautiful flooring solution.

Stock Up on Engineered Hardwood: Wholesale Options Available!

FAQs:

Do Engineered Wood Floors Scratch Easily?

Due to their protective top layer, engineered wood floors are generally more resistant to scratching than solid hardwood floors. However, they are still susceptible to scratches under certain conditions.

Are Engineered Wood Floors Waterproof Or Water-Resistant?

Engineered wood floors are more water-resistant than solid hardwood floors but not completely waterproof. Proper cleaning after spills is essential to prevent water damage.

Do Dogs Nails Scratch Engineered Hardwood Floors?

While engineered wood floors are more resistant to scratches, dog nails can still cause damage. Keeping pets’ nails trimmed and using rugs or protective pads can help minimize potential scratches.

What is the Best Thickness for Engineered Wood Flooring?

The ideal thickness depends on the subfloor and the room’s purpose. Common thicknesses range from 3/8 to 3/4 inches. Thicker options offer better durability.

Can you put Polyurethane on Engineered Wood Flooring?

We don’t recommend applying additional polyurethane to prefinished engineered wood floors. The manufacturer uses a factory finish that should remain the same.

How do I Protect my Engineered Hardwood Floors in my Kitchen?

To protect engineered hardwood floors in the kitchen, use rugs in high-traffic areas, promptly clean up spills, and avoid excessive moisture. Consider using mats near sinks and entryways

How soon can you walk on engineered hardwood floors?

The time it takes for engineered hardwood floors to cure can vary. Generally, you can walk on them after 24 to 48 hours, but following the manufacturer’s recommendations for specific products is advisable.